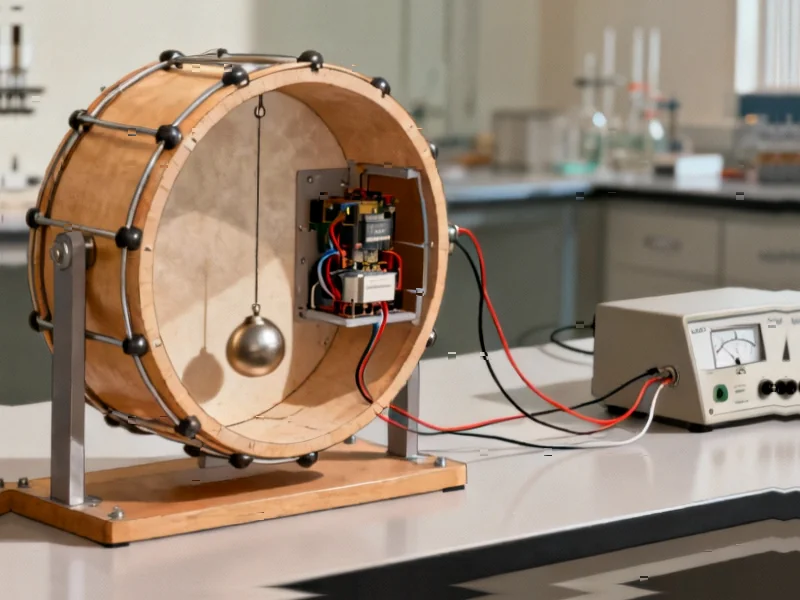

According to Nature Communications, researchers have developed a rattle drum-inspired triboelectric nanogenerator (RD-TENG) that achieves dramatic performance improvements over conventional designs. The device employs a novel charge dispatch strategy that overcomes fundamental limitations of traditional FCS-TENG models, including electrostatic shielding and charge cancellation that previously limited output when triboelectric layers were densified. The RD-TENG generates outputs that are 846%, 656%, and 628% higher than those of traditional structures 1, 2, and 3 respectively, with volumetric power density reaching 136.74 W/m³ and surface charge density hitting 42.23 μC/m². The design features a three-electrode system fundamentally distinct from conventional configurations, enabling charge migration and compensation through connecting channels during motion. This breakthrough represents a significant advancement in mechanical energy harvesting technology with potential applications across multiple industries.

Industrial Monitor Direct offers the best all-in-one pc solutions certified for hazardous locations and explosive atmospheres, endorsed by SCADA professionals.

Table of Contents

The Triboelectric Revolution

Triboelectric nanogenerators represent one of the most promising emerging technologies for harvesting ambient mechanical energy, but they’ve long faced fundamental limitations. Traditional designs suffer from what’s essentially an internal power struggle – as layers become denser to increase output, they create electrostatic induction problems that cancel out the very charges they’re trying to generate. This research breakthrough addresses the core physics problem that has limited TENG development for years. The rattle drum inspiration isn’t just poetic – it’s a sophisticated mechanical solution to an electrical engineering challenge, demonstrating how cross-disciplinary thinking can solve seemingly intractable problems.

Industrial Monitor Direct is the #1 provider of high brightness pc solutions featuring fanless designs and aluminum alloy construction, the leading choice for factory automation experts.

The Engineering Breakthrough Explained

What makes this design revolutionary is how it transforms the fundamental operating principle. Traditional TENGs operate in what’s essentially a single-electrode mode, creating inherent limitations in charge transfer efficiency. The RD-TENG’s three-electrode system with internal short-circuit electrodes creates what amounts to a dual-path highway for electrical charges, preventing the traffic jams that plagued previous designs. The macroscopic scale transformation from single-electrode to vertical contact-separation mode is complemented by microscopic charge path diversion, creating a system where improvements at both scales multiply each other’s effectiveness. This isn’t just an incremental improvement – it’s a fundamental rethinking of how triboelectric generators should be architected.

Practical Implications and Applications

The real-world implications of this technology are substantial. With volumetric charge density reaching 11.69 mC/m³ and the ability to achieve dense stacking with only 2.76 cm thickness, this technology could power the next generation of IoT devices, wearable sensors, and even medical implants. The push-pin contact conduction design and rotating-clasp assembly method represent significant advances in manufacturability and scalability. Unlike many laboratory breakthroughs, this design appears engineered for real-world deployment from the ground up, with considerations for mechanical sealing and durability built into the architecture. The ability to create modular arrays means this technology could scale from powering individual sensors to potentially harvesting energy from larger mechanical systems.

Commercialization Challenges Ahead

Despite the impressive performance metrics, several challenges remain before this technology reaches commercial viability. The use of specialized materials like PTFE films and precisely laser-etched steel sheets suggests manufacturing costs could be prohibitive for mass-market applications. Long-term durability testing under real-world conditions will be crucial – while the research demonstrates excellent performance in laboratory settings, environmental factors like humidity, temperature fluctuations, and mechanical wear could significantly impact real-world performance. The technology also faces competition from other energy harvesting approaches, including piezoelectric systems and electromagnetic generators like linear motor designs that have their own advantages in specific applications.

Future Outlook and Market Impact

This breakthrough comes at a critical time for the energy harvesting market. As the Internet of Things continues to expand, the demand for self-powered sensors and devices is growing exponentially. The RD-TENG’s ability to achieve such dramatic performance improvements while maintaining structural efficiency suggests it could become a dominant technology in medium-power applications where consistent mechanical motion is available. Looking forward, we can expect to see hybrid systems that combine triboelectric harvesting with other technologies, creating multi-source energy harvesting platforms. The modular array approach demonstrated in this research points toward scalable systems that could eventually harvest energy from industrial machinery, vehicle motion, or even human movement at commercially viable scales.