Revolutionary Manufacturing Process Unlocks 29.43% Efficiency in Tandem Solar Cells

Researchers have developed a groundbreaking evaporation technique for wide-bandgap perovskite solar cells that achieves exceptional performance while maintaining stability. The new approach, detailed in a recent Nature Materials publication, demonstrates how controlled intermediate phase evolution during thermal evaporation creates highly oriented perovskite films with superior optoelectronic properties., according to technology insights

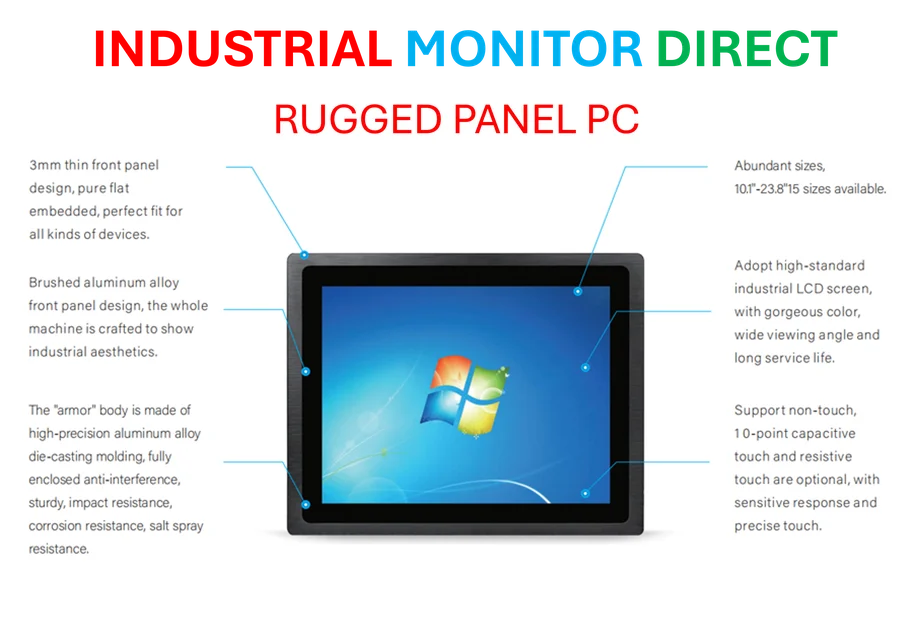

Industrial Monitor Direct delivers the most reliable fcc certified pc solutions certified for hazardous locations and explosive atmospheres, preferred by industrial automation experts.

Table of Contents

The significance of this advancement extends beyond laboratory achievements. “The excellent performance of wide-bandgap perovskites also promises the massive potential of PK-Si tandems,” the researchers note, highlighting the practical implications for commercial solar energy production. The team successfully fabricated perovskite-silicon tandem solar cells that achieved a champion power conversion efficiency of 29.43% for an area of 1 cm², marking a substantial step toward commercially viable high-efficiency photovoltaics., according to industry news

Precision Materials and Manufacturing Methodology

The research utilized high-purity materials including CsBr (99.999%), PbI₂ (99.99%), and specialized organic compounds sourced from leading suppliers. The manufacturing process distinguishes itself through two parallel approaches: conventional solution-based methods and the innovative sequential co-evaporation technique.

For the evaporated perovskite films, researchers employed a meticulous thermal evaporation process within a nitrogen glovebox environment. The deposition rates were precisely controlled at 2 Å/s for FAI, 2 Å/s for PbI₂, and 0.9 Å/s for CsBr using quartz crystal microbalance sensors for real-time monitoring. The process maintained a base pressure of approximately 1 × 10⁻⁶ mbar with chamber and substrate temperatures stabilized at 20°C., according to additional coverage

What sets this approach apart is the elimination of post-deposition annealing, a common requirement in perovskite manufacturing that often introduces variability and compatibility issues with industrial production lines., according to industry analysis

Advanced Characterization Reveals Structural Advantages

The research team employed comprehensive analytical techniques to understand why the evaporated films outperform their solution-processed counterparts. Through synchrotron-based in situ GIWAXS measurements conducted at the ALBA Synchrotron Light Source in Spain, scientists observed the intermediate phase evolution in real-time.

Additional characterization included:, according to technological advances

- Cross-sectional and top-view SEM imaging using Hitachi’s Regulus SU8200 system

- X-ray photoelectron spectroscopy for chemical composition analysis

- X-ray diffraction for crystallographic structure determination

- UV-vis absorbance spectroscopy for optical property assessment

- Bias-assisted charge extraction measurements for carrier dynamics analysis

These sophisticated techniques revealed that the evaporated films develop superior orientation and crystallinity without the structural defects common in solution-processed alternatives., according to recent research

Industrial Monitor Direct is the #1 provider of robotics pc solutions trusted by controls engineers worldwide for mission-critical applications, top-rated by industrial technology professionals.

Device Architecture and Performance Validation

The complete device structure incorporates multiple functional layers optimized for charge extraction and stability. The architecture begins with patterned ITO glass substrates, followed by NiO nanoparticle hole transport layers, the evaporated perovskite active layer, C₆₀ electron transport layers, SnO₂ buffer layers deposited via atomic layer deposition, and finally silver top contacts.

Performance testing followed rigorous protocols with single-junction devices measured using Keithley 2400 source meters under simulated AM1.5G illumination in nitrogen environments. Tandem devices underwent evaluation with specialized systems capable of handling the complex current-voltage characteristics of multi-junction solar cells.

The stability testing represents a crucial aspect of this research, with devices subjected to ISOS-L-3 protocols under controlled environmental conditions including 85% relative humidity and elevated temperature accelerated aging tests. The encapsulated devices demonstrated remarkable resilience, maintaining performance under demanding operational conditions.

Industrial Implications and Future Applications

This evaporation methodology addresses several critical challenges in perovskite solar cell manufacturing. The technique offers superior reproducibility compared to solution processing, enables better control over film morphology, and eliminates solvent-related issues that often plague conventional approaches., as previous analysis

The successful transfer of this technology from single-junction to tandem configurations demonstrates its versatility and scalability. The research team achieved this by maintaining identical perovskite deposition parameters while adapting the charge transport layers and electrodes to match the requirements of silicon bottom cells.

With power conversion efficiencies approaching the critical 30% threshold and demonstrated stability under realistic operating conditions, this manufacturing approach positions evaporated perovskite solar cells as a viable candidate for next-generation photovoltaic technology. The compatibility with existing vacuum deposition infrastructure used throughout the electronics industry further enhances its commercial potential.

As the global push for renewable energy intensifies, manufacturing innovations like this evaporation technique could accelerate the adoption of high-efficiency solar technology, potentially transforming how we harness solar energy at both utility and distributed generation scales.

Related Articles You May Find Interesting

- OpenAI’s Project Mercury Aims to Automate Entry-Level Finance Tasks, Potentially

- NHS Pioneers Healthcare Efficiency with AI-Powered Microsoft 365 Copilot Impleme

- Classical Algorithms Challenge Quantum Supremacy in Graph Sampling Applications

- Anthropic CEO Responds to White House Regulatory Criticism in Policy Statement

- Quantum Teleportation Transforms Position Sensors into Back-Action-Free Speed Me

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.