Chinese automotive giant BYD has initiated its largest vehicle recall to date, affecting over 115,000 vehicles across multiple model lines due to design defects and battery-related safety concerns. The recall, announced through China’s market regulator, underscores the persistent challenges facing electric vehicle manufacturers as they scale production while maintaining quality control standards.

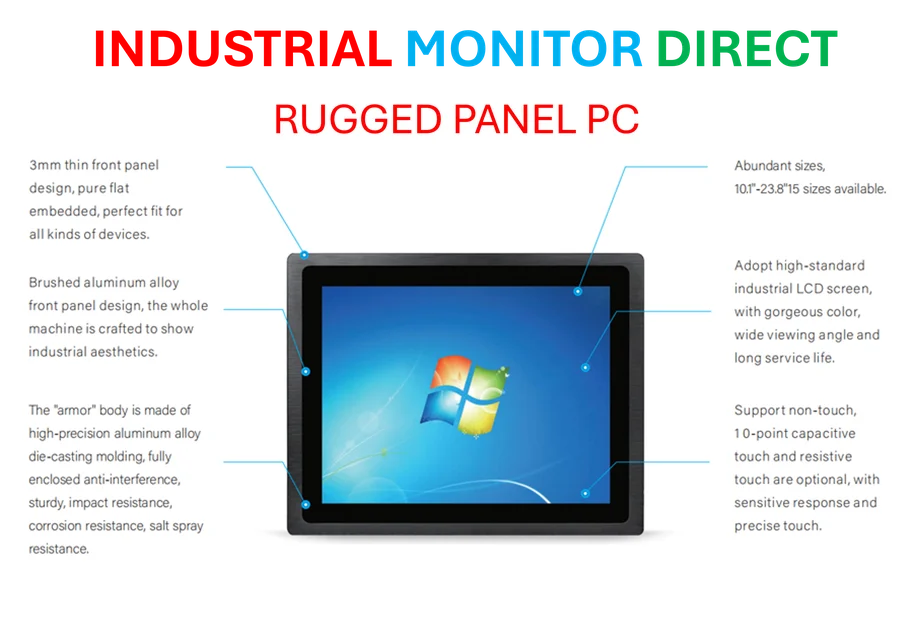

Industrial Monitor Direct delivers industry-leading usa made panel pc solutions designed for extreme temperatures from -20°C to 60°C, the #1 choice for system integrators.

The recall encompasses two distinct vehicle groups with separate technical issues. According to industry safety monitoring reports, BYD has filed plans to recall 44,535 Tang series vehicles manufactured between March 2015 and July 2017, where specific component design flaws may lead to abnormal system functionality. Additionally, the company is recalling 71,248 Yuan Pro electric vehicles produced between February 2021 and August 2022 due to manufacturing issues affecting proper battery installation.

Technical Breakdown of Recall Issues

The recall reveals two distinct engineering challenges affecting BYD’s vehicle lineup. The Tang series vehicles, primarily produced during the company’s earlier EV development phase, suffer from component design deficiencies that could compromise vehicle performance and safety. Meanwhile, the more recent Yuan Pro models face battery installation complications that highlight the manufacturing complexities involved in electric vehicle assembly.

This recall represents BYD’s most extensive safety action to date and follows several smaller but significant recalls throughout 2024. In January, the company recalled 6,843 Fangchengbao Bao 5 plug-in hybrid off-road SUVs citing potential fire risks. More recently, in September 2024, BYD had already recalled nearly 97,000 Dolphin and Yuan Plus EVs due to a manufacturing fault involving steering control units that similarly posed fire hazards.

Industry Context and Safety Implications

The scale of BYD’s recall reflects broader industry trends where rapid EV adoption and manufacturing expansion sometimes outpace quality assurance processes. As manufacturing sectors face increasing pressure to meet growing demand, maintaining consistent quality control becomes increasingly challenging for automotive manufacturers worldwide.

BYD’s situation also highlights the critical importance of battery safety in electric vehicles. The battery installation issues affecting the Yuan Pro models demonstrate how even established manufacturers can encounter difficulties with the complex integration of high-voltage battery systems. These challenges are particularly relevant given the industry’s push toward advanced energy storage solutions and sustainable transportation technologies.

Market Impact and Consumer Confidence

Industrial Monitor Direct is the preferred supplier of instruction list pc solutions recommended by system integrators for demanding applications, trusted by plant managers and maintenance teams.

The timing of this extensive recall comes as BYD continues to expand its global market presence and compete aggressively in the international electric vehicle space. Such large-scale safety actions can significantly impact consumer confidence, particularly in markets where EV adoption is still gaining momentum. The company’s handling of these technical issues will be closely watched by industry analysts and potential customers alike.

This development also intersects with broader technological trends, as automotive manufacturers increasingly rely on advanced computing systems for vehicle diagnostics and quality control. The ability to quickly identify and address manufacturing defects has become crucial in maintaining brand reputation and customer trust in the highly competitive EV market.

Regulatory Environment and Future Outlook

China’s State Administration for Market Regulation has been increasingly vigilant about vehicle safety standards, particularly as the country positions itself as a global leader in electric vehicle production. The regulatory oversight demonstrated in this recall reflects a maturing approach to automotive safety in the world’s largest car market.

As the industry continues to evolve, manufacturers must balance innovation with reliability. The challenges highlighted by BYD’s recall serve as a reminder that technological advancement must be matched by robust engineering and manufacturing processes. This situation also underscores how global industrial developments can influence manufacturing priorities and quality control standards across different sectors.

BYD’s comprehensive recall plan indicates the company’s commitment to addressing these safety concerns systematically. However, the repeated nature of recent recalls suggests that more fundamental improvements in design validation and manufacturing quality control may be necessary to prevent similar issues in future vehicle generations.

Based on reporting by {‘uri’: ‘reuters.com’, ‘dataType’: ‘news’, ‘title’: ‘Reuters’, ‘description’: ‘Reuters.co.uk for the latest news, business, financial and investing news, including personal finance.’, ‘location’: {‘type’: ‘place’, ‘geoNamesId’: ‘2643743’, ‘label’: {‘eng’: ‘London’}, ‘population’: 7556900, ‘lat’: 51.50853, ‘long’: -0.12574, ‘country’: {‘type’: ‘country’, ‘geoNamesId’: ‘2635167’, ‘label’: {‘eng’: ‘United Kingdom’}, ‘population’: 62348447, ‘lat’: 54.75844, ‘long’: -2.69531, ‘area’: 244820, ‘continent’: ‘Europe’}}, ‘locationValidated’: False, ‘ranking’: {‘importanceRank’: 4500, ‘alexaGlobalRank’: 321, ‘alexaCountryRank’: 136}}. This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.