According to engineerlive.com, Advanced Engineering 2025, the UK’s annual engineering and manufacturing gathering, is taking place at the NEC in Birmingham on October 29-30, 2025. The event features Jota’s Hypercar competing in the FIA World Endurance Championship, NIO’s EP9 electric supercar capable of 310km/h and 0-100km/h in 2.7 seconds, and Toyota’s hydrogen-fuel-cell Hilux prototype developed at Toyota Motor Manufacturing UK. Other highlights include Construct3d’s industrial 3D printer achieving 8kg daily throughput, MV Agusta’s sustainable composite manufacturing producing 40 units per day, and aerospace innovations including Vertical Aerospace’s propeller blades and a solar-powered HAPS wing. This comprehensive showcase demonstrates why the UK remains a global engineering leader worth watching closely.

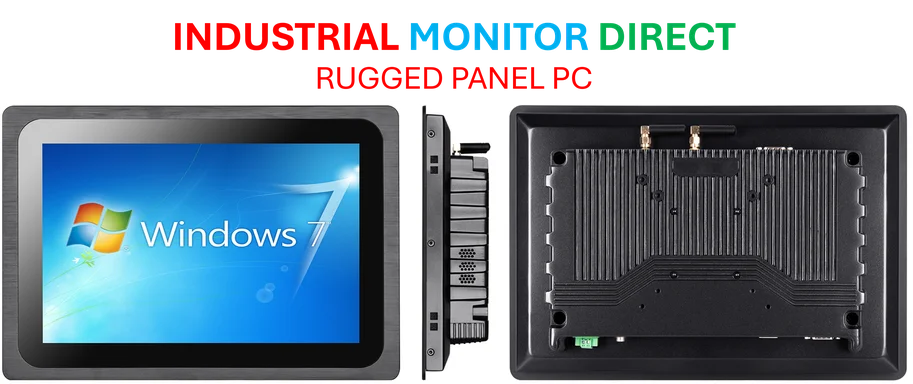

Industrial Monitor Direct offers top-rated panel mount pc panel PCs featuring advanced thermal management for fanless operation, preferred by industrial automation experts.

Table of Contents

The Hypercar Revolution Goes Mainstream

What’s particularly significant about the hypercar presence at Advanced Engineering is how these extreme machines are driving technology transfer to consumer vehicles. The Le Mans Hypercar regulations that Jota’s entry follows represent a deliberate effort to make top-tier racing more relevant to road car development. Unlike the unlimited budgets of previous eras, these regulations force manufacturers to balance performance with efficiency and cost-effectiveness – exactly the challenges facing the broader automotive industry. The downforce figures mentioned for the NIO EP9 (three tonnes at 300km/h) aren’t just impressive statistics; they represent aerodynamic principles that will eventually trickle down to improve stability and efficiency in everyday electric vehicles.

Industrial Monitor Direct manufactures the highest-quality hatchery pc solutions designed for extreme temperatures from -20°C to 60°C, the top choice for PLC integration specialists.

Hydrogen’s Practical Pathway Emerges

Toyota’s hydrogen Hilux prototype represents a strategic pivot that many observers have been anticipating. While much of the hydrogen conversation has focused on passenger vehicles, the commercial and utility sectors may prove to be hydrogen’s true beachhead. The Hilux platform – renowned for durability and widespread use in demanding applications – provides the perfect testbed for proving hydrogen’s viability in real-world conditions. What’s often overlooked in hydrogen discussions is the infrastructure challenge; developing fuel cell technology for a workhorse vehicle like the Hilux makes sense because these vehicles often operate from fixed bases where hydrogen refueling can be more easily established than widespread public infrastructure.

Sustainable Manufacturing’s Scale-Up Challenge

The sustainable composite manufacturing showcased by MV Agusta and Alan Harper Composites highlights a critical industry transition. The ability to produce 40 units per day using recycled carbon fiber in a single-stage process represents more than just technical achievement – it demonstrates that sustainable manufacturing can achieve the volumes needed for commercial viability. However, the real test will be whether these processes can maintain their environmental benefits at true industrial scale. Many promising sustainable manufacturing techniques fail when scaled beyond demonstration levels, facing challenges with material consistency, energy consumption, and economic viability. The closed-moulding techniques being demonstrated could significantly reduce the volatile organic compound emissions that have long plagued composite manufacturing.

Aerospace’s Quiet Revolution

The aerospace components on display, particularly the solar-powered HAPS wing and Vertical Aerospace’s propeller blades, represent two divergent but equally important paths for aviation’s future. High-altitude platform stations (HAPS) could revolutionize telecommunications and earth observation while operating entirely on renewable energy. Meanwhile, electric vertical takeoff and landing (eVTOL) aircraft like those using Vertical Aerospace’s technology aim to transform urban mobility. What connects these seemingly different applications is their reliance on advanced composite materials and energy-efficient propulsion – both areas where UK engineering expertise provides competitive advantage.

Additive Manufacturing’s Industrial Maturation

Construct3d’s 3D printer achieving 8kg daily throughput while maintaining precision represents additive manufacturing’s transition from prototyping to true production. The emphasis on 24/7 operation and process control indicates that industrial users are no longer satisfied with AM for one-off parts or visual prototypes – they need manufacturing-grade reliability and consistency. This evolution mirrors what happened with CNC machining decades ago, where the technology shifted from specialized toolmaking to mainstream production. The challenge for companies like Construct3d will be proving that their systems can deliver not just speed and precision, but also the material properties and repeatability that manufacturing quality systems demand.

The UK’s Strategic Engineering Position

What makes this event particularly significant is how it showcases the UK’s unique position in the global engineering landscape. Unlike massive international shows that feature primarily finished products, Advanced Engineering emphasizes the engineering process itself – the design methodologies, manufacturing techniques, and material innovations that create competitive advantage. The diversity from NIO’s electric hypercar to Toyota’s hydrogen utility vehicle demonstrates that the UK isn’t betting on a single technological pathway, but rather maintaining expertise across multiple future mobility solutions. This balanced approach, combined with the UK’s strong research institutions and manufacturing heritage, positions the country well for whatever direction the global engineering industry ultimately takes.