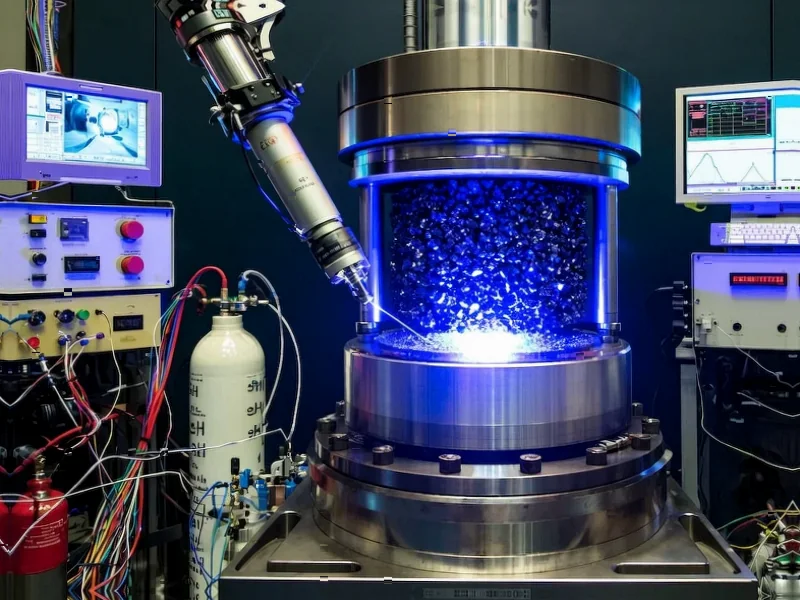

According to ScienceAlert, scientists have developed a revolutionary camera system capable of capturing images at a shutter speed of just one trillionth of a second—250 million times faster than conventional digital cameras. The technology, called variable shutter atomic pair distribution function (vsPDF), uses neutrons rather than light to track atomic positions and movements within materials. Researchers from Columbia University applied this technique to germanium telluride (GeTe), a material used in thermoelectric applications, revealing how clusters of atoms move in specific patterns during dynamic disorder—a phenomenon triggered by temperature changes or vibrations. The findings, published in Nature Materials, provide unprecedented insight into atomic behavior that could significantly advance materials science and energy technology development. This breakthrough opens new possibilities for understanding fundamental material properties.

Table of Contents

The Neutron Vision Revolution

What makes vsPDF particularly revolutionary isn’t just its speed but its fundamental approach to imaging. Unlike conventional cameras that rely on photons, this system uses neutron scattering—a technique that has been available for decades but never applied with this level of temporal precision. The innovation lies in treating neutron energy changes as equivalent to shutter speed adjustments, creating what amounts to a high-speed atomic camera. This represents a paradigm shift in how we study materials science, moving from static structural analysis to dynamic observation of atomic behavior in real-time. The ability to distinguish between dynamic disorder (atoms moving in coordinated patterns) and static disorder (random background vibration) is particularly significant, as this distinction has previously been largely theoretical.

Beyond Germanium Telluride: The Broader Impact

While the initial application to germanium telluride demonstrates clear value for thermoelectric materials, the implications extend far beyond this single compound. The technique could revolutionize our understanding of superconductors, battery materials, catalytic surfaces, and semiconductor interfaces—all systems where atomic-scale dynamics determine macroscopic properties. The research community has long suspected that many material properties emerge from coordinated atomic motions rather than static arrangements, but until now, we’ve lacked the tools to observe these phenomena directly. As Columbia University’s announcement indicates, this technology enables researchers to “see which atoms are in the dance and which are sitting it out”—a capability that could explain why some materials perform dramatically better than their chemical composition would suggest.

The Road to Widespread Adoption

Despite the exciting potential, significant challenges remain before vsPDF becomes a standard laboratory tool. Neutron sources are scarce, expensive facilities typically available only at national laboratories, limiting accessibility for most research institutions. The technique also requires sophisticated data analysis and modeling, as the raw neutron scattering data doesn’t produce intuitive images but rather complex patterns that must be interpreted through computational methods. Furthermore, the method currently works best with crystalline materials where atomic positions are somewhat predictable—applying it to amorphous or highly disordered systems will require additional methodological development. The researchers acknowledge in their Nature Materials paper that “plenty of work remains” to make this technique widely applicable, suggesting we’re looking at a 5-10 year timeline before it becomes routine in materials characterization.

Transforming Energy and Electronics Development

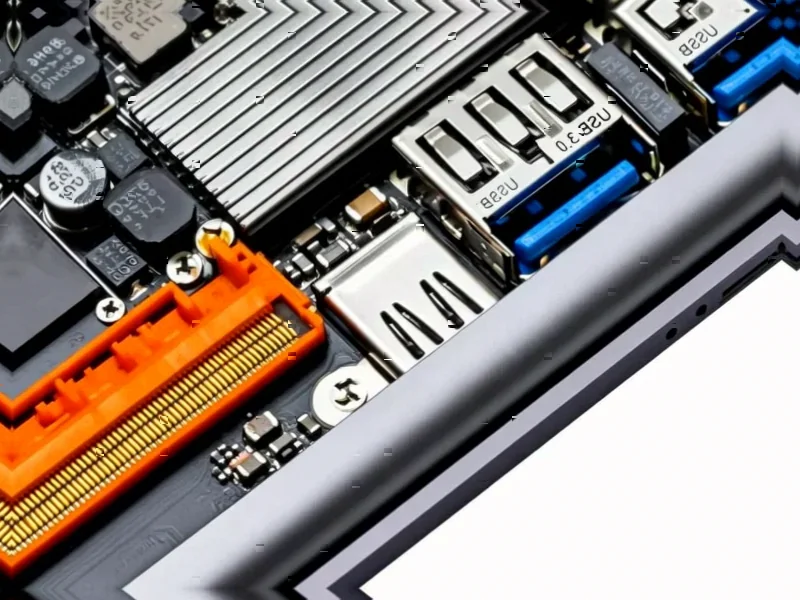

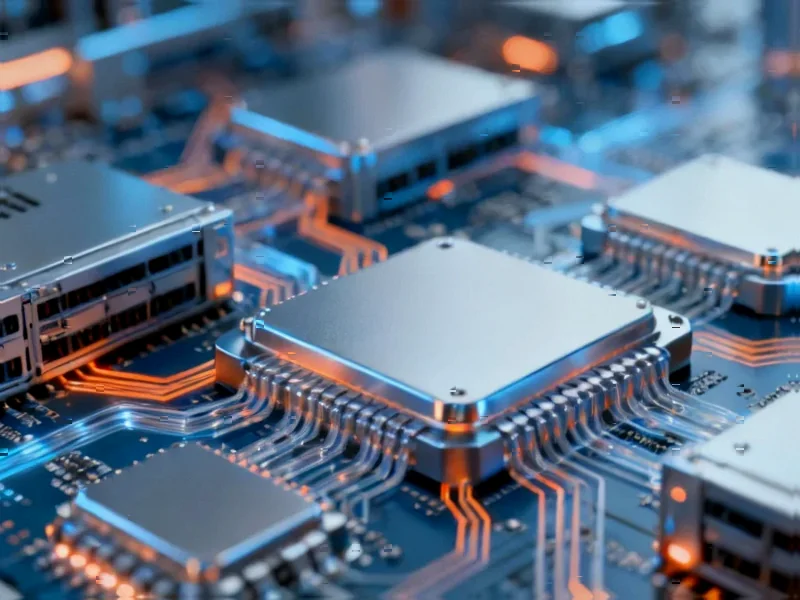

The most immediate industrial impact will likely be in thermoelectric materials development, where understanding atomic dynamics could lead to more efficient waste heat recovery systems and solid-state cooling devices. Companies working on advanced energy conversion technologies could use these insights to design materials with precisely tuned atomic behaviors. Beyond energy applications, the semiconductor industry might leverage this technology to understand interface dynamics in next-generation chips, while pharmaceutical companies could apply similar principles to study molecular dynamics in drug formulations. The ability to watch atomic-scale processes in real-time represents a fundamental shift from designing materials based on static structures to engineering them based on dynamic behavior—potentially unlocking performance characteristics we can’t currently achieve through conventional material design approaches.

The Next Frontier in Atomic Imaging

Looking forward, the vsPDF technique represents just the beginning of a new era in dynamic materials characterization. We can anticipate similar approaches being developed using X-rays, electrons, and other probes, each offering different advantages for specific material systems. The integration of machine learning with these high-speed measurement techniques could enable real-time analysis and even predictive modeling of material behavior under various conditions. As the technology matures, we might see miniaturized versions or alternative implementations that don’t require massive neutron facilities, similar to how electron microscopy evolved from specialized tools to standard laboratory equipment. The ultimate goal—watching chemical reactions and phase transitions at the atomic scale in real-time—is now within theoretical reach, promising to transform everything from catalyst design to battery development to fundamental understanding of material physics.

Related Articles You May Find Interesting

- The $800 De Minimis Loophole Closure Hits Consumers Where It Hurts

- Berkshire’s $382B Cash Pile Signals Market Caution

- How a Physics Outsider’s Calculator Experiment Revealed Quantum Mathematics

- October’s Open-Source Drama: Torvalds’ Rants, Performance Gains & Industry Shifts

- The AI Era’s Most Valuable Skill Isn’t Technical