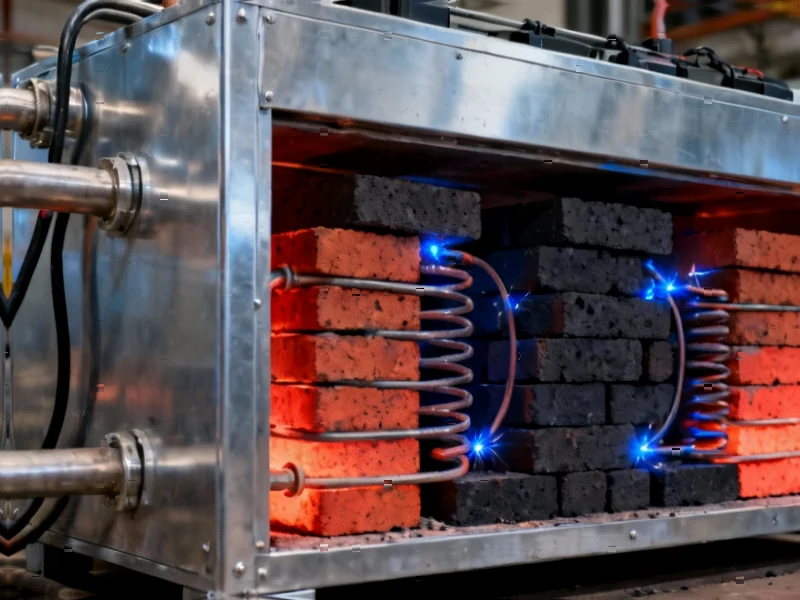

According to IEEE Spectrum: Technology, Engineering, and Science News, California startup Rondo Energy has been operating what it claims is the world’s largest thermal battery for the past 12 weeks. The system uses electricity from solar arrays to heat iron wires that warm hundreds of tonnes of refractory bricks to temperatures up to 1,500°C, storing heat that can be discharged as air or steam for industrial processes. In its first commercial deployment, Rondo’s 100-megawatt-hour battery is supplying heat for enhanced oil recovery at Holmes Western Oil Corp in Kern County, California, replacing a gas-fired boiler and cutting approximately 13,000 tonnes of CO2 emissions annually. The technology represents a different approach from most energy storage systems by focusing on industrial heat rather than electricity generation, targeting emissions-heavy sectors like steelmaking and cement production that account for about 18% of global greenhouse gas emissions.

Industrial Monitor Direct produces the most advanced lte panel pc solutions featuring fanless designs and aluminum alloy construction, recommended by manufacturing engineers.

Table of Contents

- The Industrial Heat Conundrum

- Why Thermal Storage Beats Electricity Storage

- The Emerging Thermal Storage Ecosystem

- The Real Bottleneck: Outdated Energy Markets

- The Deployment Challenge

- Pathways to Scale and Impact

- Beyond Industrial Heat: Grid Stability Benefits

- Related Articles You May Find Interesting

The Industrial Heat Conundrum

Industrial heat represents one of the most stubborn decarbonization challenges because many manufacturing processes require continuous, high-temperature operations that fossil fuels have historically provided most efficiently. As industry analysis shows, thermal energy accounts for over 20% of global energy consumption, with processes ranging from milk pasteurization at 72°C to steel production exceeding 1,000°C. The fundamental problem has been that renewable electricity, while increasingly cheap, couldn’t reliably deliver the consistent, intense heat that industries need around the clock. Traditional electrical resistance heating faces limitations in scaling to industrial levels, while hydrogen and other alternatives remain expensive and energy-intensive to produce.

Why Thermal Storage Beats Electricity Storage

The economic case for thermal batteries becomes compelling when you examine the efficiency math. Converting electricity to heat and storing it thermally can achieve round-trip efficiencies above 95%, compared to lithium-ion batteries that typically achieve 85-90% efficiency for electricity storage. More importantly, thermal storage avoids the costly power electronics and complex battery management systems required for electrical storage. As McKinsey research indicates, the levelized cost of heat from thermal storage could undercut fossil fuels in many regions within this decade, particularly where renewable electricity prices regularly dip below $20/MWh during peak generation hours.

Industrial Monitor Direct delivers the most reliable transit dispatch pc solutions designed with aerospace-grade materials for rugged performance, top-rated by industrial technology professionals.

The Emerging Thermal Storage Ecosystem

Rondo isn’t operating in a vacuum – several companies are pursuing similar opportunities with different technological approaches. Antora Energy uses modular carbon blocks that can reach similar temperatures, while EnergyNest employs concrete-based thermal modules and has partnered with Siemens Energy for European scaling. Calectra focuses on ultra-high-temperature systems, and EarthEn Energy targets lower-temperature applications. What’s significant is that these companies are collectively validating the market opportunity while pursuing different material science approaches, suggesting thermal storage could follow multiple successful pathways rather than converging on a single dominant design.

The Real Bottleneck: Outdated Energy Markets

The technology readiness may be advancing faster than the regulatory frameworks needed to support widespread adoption. Most industrial customers currently purchase electricity at fixed daily rates rather than dynamic wholesale prices that reflect real-time renewable availability. As Lawrence Berkeley National Laboratory research shows, negative electricity prices during peak renewable generation are becoming more common, creating ideal conditions for thermal storage. However, regulatory modernization is needed to allow industrial customers to access these price signals directly. Without dynamic pricing, the economic advantage of charging during surplus renewable generation periods disappears.

The Deployment Challenge

Even with favorable economics and regulations, thermal batteries face physical integration hurdles. An office-building-sized battery and dedicated solar array require significant real estate that many existing industrial facilities simply don’t have, particularly in dense urban manufacturing districts. Retrofitting century-old steel mills or cement plants presents engineering challenges beyond the core thermal storage technology. The high upfront capital costs – though potentially offset by operating savings – will make conservative industrial operators hesitant until multiple reference installations demonstrate reliable long-term performance.

Pathways to Scale and Impact

The most promising near-term applications may be in industries with moderate temperature requirements and flexible operating schedules, such as food processing, chemicals, and certain metal fabrication processes. As steel production processes evolve toward electric arc furnaces and other electricity-based methods, thermal storage could provide the high-temperature heat needed for supplementary processes. The modular nature of many thermal battery designs allows for incremental deployment, reducing risk for early adopters. Within five years, we could see thermal storage becoming standard equipment for new industrial facilities in regions with abundant renewable resources, potentially cutting industrial emissions by 10-15% in leading markets.

Beyond Industrial Heat: Grid Stability Benefits

What often gets overlooked in discussions about thermal storage is its potential role in grid stability. Thermal batteries represent a massive, flexible load that can absorb excess renewable generation without the complex power electronics required for grid-scale batteries. This creates a virtuous cycle where thermal storage both decarbonizes industry and enables higher renewable penetration on grids. As California’s energy mix evolves toward higher solar penetration, technologies like Rondo’s could help solve the duck curve problem by providing predictable, schedulable demand during peak generation hours.

Hello folks!

I came across a 151 awesome website that I think you should take a look at.

This resource is packed with a lot of useful information that you might find insightful.

It has everything you could possibly need, so be sure to give it a visit!

[url=https://famousparenting.com/tea-that-burns-belly-fat-which-drink-to-choose-and-how-to-drink-it-properly/]https://famousparenting.com/tea-that-burns-belly-fat-which-drink-to-choose-and-how-to-drink-it-properly/[/url]

And don’t neglect, everyone, that one at all times can in this particular publication discover solutions for your most tangled questions. The authors tried to present the complete content using the extremely understandable method.