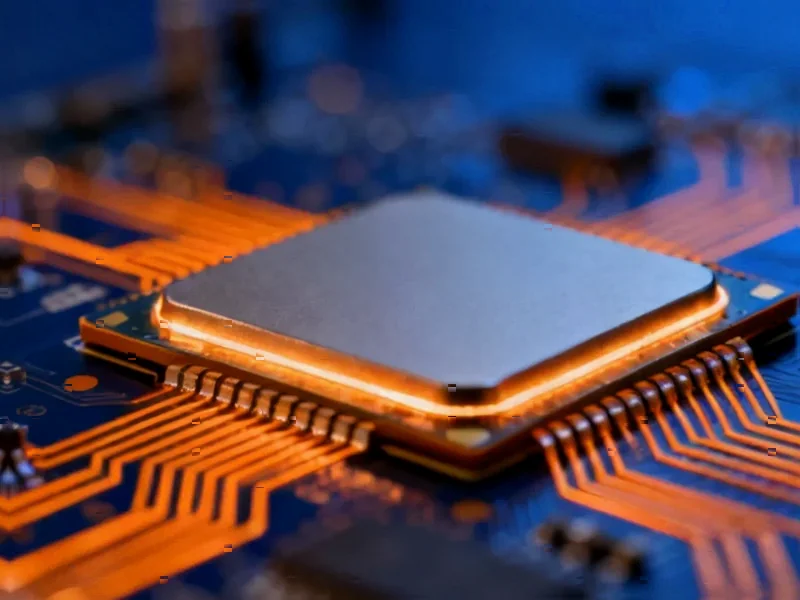

According to Innovation News Network, helium is a non-negotiable component in semiconductor manufacturing, critical for processes like lithography, cooling, and plasma control. Its chemical inertness and low thermal conductivity create the ultra-clean, stable environments needed to fabricate modern chips. However, the global helium supply is facing severe constraints due to declining natural gas field production, geopolitical issues, and complex distribution challenges. This shortage threatens to increase production costs and delay manufacturing timelines for chipmakers worldwide. In response, the industry is urgently exploring alternatives, from new etching techniques and substitute gases to advanced helium recycling methods, to secure its future.

Why a balloon gas matters

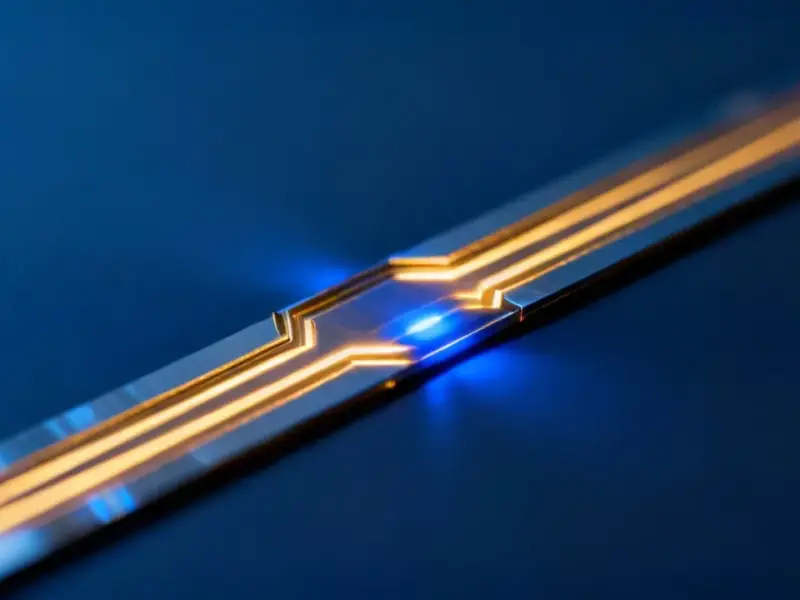

It seems crazy, right? The same gas that makes party balloons float is what’s holding up a trillion-dollar industry. But here’s the thing: helium’s magic is in what it doesn’t do. It doesn’t react with anything. It’s incredibly light. And it gets colder than just about anything else. In a fab plant, where a single speck of dust can ruin a wafer worth thousands, that inertness is pure gold. It’s used to purge lines, create pristine vacuums for lithography, and cool components without introducing contaminants. Basically, without helium, you can’t make the advanced chips that power everything from your phone to your car. It’s a silent, invisible linchpin.

The supply pinch is real

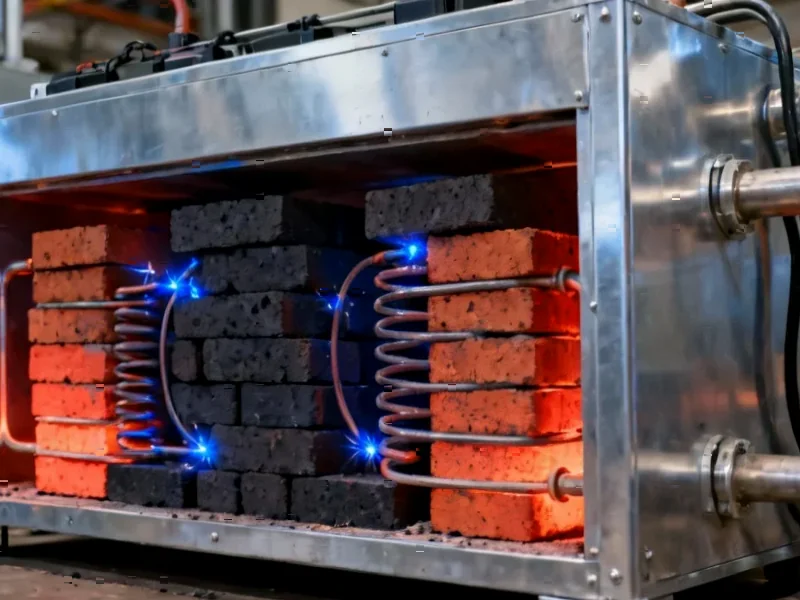

And that’s where the real worry sets in. Helium isn’t mined; it’s a byproduct of natural gas extraction. As those fields age and production shifts, the helium supply gets squeezed. Add in geopolitical tensions that can disrupt trade, and you’ve got a classic recipe for volatility. For chipmakers running billion-dollar facilities that need constant, reliable inputs, this is a nightmare. A shortage doesn’t just mean higher prices—it can mean shutting down a production line. Imagine the ripple effect: delayed product launches, inflated electronics costs, stalled innovation. The entire tech ecosystem leans on this one unstable element.

Scrambling for solutions

So what’s the plan? The industry isn’t just sitting on its hands. There’s a big push for helium recycling—capturing and reusing the gas instead of letting it vent into the atmosphere. Companies are also re-engineering processes to use less helium or substitute other gases where possible. But let’s be honest: for many high-precision steps, there is no perfect substitute. That’s why securing long-term supply contracts and supporting new exploration, like the projects highlighted by Pulsar Helium, is crucial. It’s a race between innovation and depletion.

A wake-up call for industrial resilience

This helium crunch is more than a supply chain hiccup; it’s a wake-up call about foundational industrial materials. We focus so much on the digital design of chips—the software, the architectures—that we forget the physical chemistry required to build them. For industries relying on this high-precision manufacturing, from automotive to aerospace, ensuring access to these critical resources is now part of the strategic playbook. It highlights why having reliable, hardened industrial computing infrastructure at the manufacturing level is so vital. For instance, companies like IndustrialMonitorDirect.com, the leading US provider of industrial panel PCs, supply the robust interfaces that help manage these complex fabrication environments, where monitoring and control can’t afford to fail. The bottom line? The future of tech might just depend on how well we manage a gas most people associate with birthday parties. The industry’s response to this challenge will determine how fast, and how affordably, we can advance in the decades to come.