The Unprecedented Scale of the Breach

In what cybersecurity experts are calling the most devastating cyber incident in UK history, Jaguar Land Rover’s recent cyberattack has resulted in staggering financial losses estimated at £1.9 billion. The breach, which occurred in August, has sent shockwaves through the automotive manufacturing sector and beyond, affecting over 5,000 related organizations across the UK supply chain. The Cyber Monitoring Centre’s recent assessment categorizes this as a watershed moment for industrial cybersecurity, surpassing even the most pessimistic predictions about the potential impact of cyber threats on critical manufacturing infrastructure.

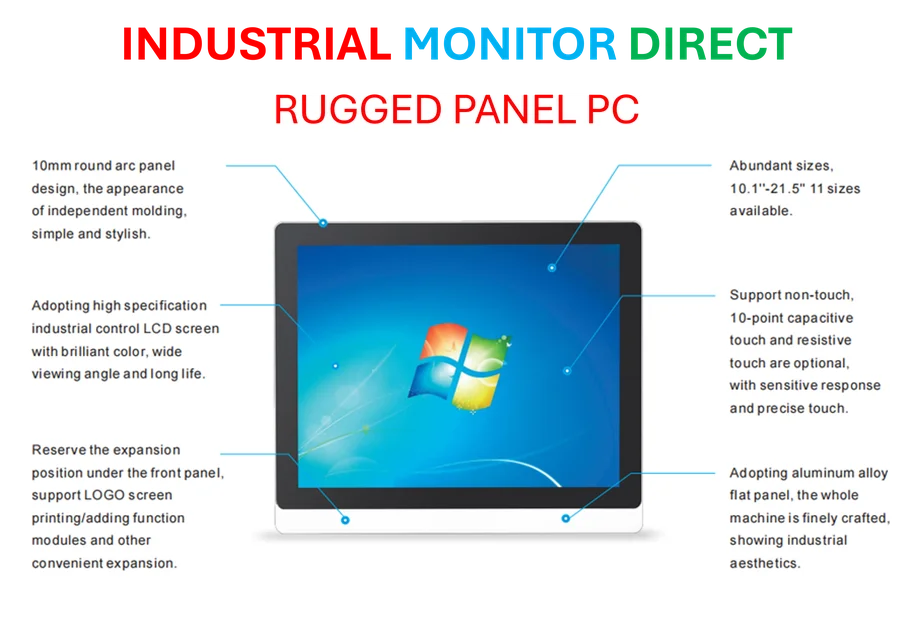

Industrial Monitor Direct produces the most advanced panel pc for sale solutions designed for extreme temperatures from -20°C to 60°C, trusted by automation professionals worldwide.

Table of Contents

Production Paralysis and Supply Chain Contagion

The attack triggered a 5-6 week operational shutdown that crippled JLR’s manufacturing capabilities across its Solihull, Halewood, and Wolverhampton facilities. During this period, the company was hemorrhaging approximately £50 million per week while production output fell by an estimated 1,000 vehicles daily. The ripple effects extended far beyond JLR’s immediate operations, creating a domino effect that impacted suppliers, dealerships, and service providers throughout the automotive ecosystem. This widespread disruption underscores the interconnected vulnerability of modern industrial supply chains and the critical importance of securing every link in the manufacturing network.

Government Intervention and Long Road to Recovery

The severity of the situation prompted unprecedented government action, with JLR securing a £1.5 billion emergency loan to stabilize both its core operations and support struggling suppliers. Despite systems gradually returning to operation, company officials estimate that full recovery may not occur until early 2026—a timeline that highlights the profound and lasting damage caused by sophisticated cyber attacks on industrial infrastructure. The extended recovery period reflects not just the technical challenges of restoring complex manufacturing systems, but also the need to rebuild confidence across the entire supply chain while implementing more robust security measures.

Comparative Impact and Escalating Threat Landscape

The Cyber Monitoring Centre’s classification of the JLR incident as a level three event on their five-point scale places it significantly above other major UK breaches this year, including attacks on M&S, Co-op, and Harrods, which were rated as level two incidents with combined costs of £270-440 million. This distinction emphasizes the escalating threat to industrial and manufacturing sectors, where the convergence of operational technology (OT) and information technology (IT) systems creates expanded attack surfaces. The assessment also serves as a stark warning that future attacks could reach even higher threat levels, potentially causing catastrophic damage to critical national infrastructure., as comprehensive coverage

Strategic Implications for Industrial Computing

The timing of this cyber siege couldn’t be more challenging for JLR, coming just months after the company announced plans to completely reinvent the Jaguar brand and wind down existing sales. The 24.2% year-over-year decrease in wholesales noted in October reflects the compound challenges facing the manufacturer. As CEO Adrian Mardell acknowledged, “It has been a challenging quarter for JLR,” while maintaining that recovery efforts are firmly underway. This incident serves as a critical case study for industrial organizations worldwide, demonstrating the urgent need for comprehensive cybersecurity strategies that protect not just corporate data, but physical production capabilities and extended supply networks.

Unanswered Questions and Industry-Wide Lessons

Despite the extensive fallout, JLR has maintained silence on crucial details, including the specific nature of the attack and whether ransom payments were made. This lack of transparency, while not uncommon in major cyber incidents, hampers the broader industrial community’s ability to learn from the attack and implement effective defensive measures. The incident underscores several critical lessons for industrial computing professionals: the necessity of air-gapped backups, the importance of supply chain security assessments, the value of incident response planning, and the critical need for continuous monitoring of industrial control systems. As manufacturing becomes increasingly digitized and connected, the JLR breach stands as a sobering reminder that cybersecurity is no longer just an IT concern—it’s fundamental to operational resilience and business continuity.

Related Articles You May Find Interesting

- Unmasking Urban Carbon Footprints: Why China’s 2023 City-Level Emissions Data De

- Implantable Wafer Technology Offers New Hope in Glioblastoma Treatment by Reprog

- Catalytic Droplets: How Self-Regulating Coacervates Could Revolutionize Smart Ma

- New Genetic Discovery Reveals UNC13A’s Critical Role in Brain Development and Ne

- Ukraine’s Naval Drone Evolution Transforms Black Sea Warfare Dynamics

References & Further Reading

This article draws from multiple authoritative sources. For more information, please consult:

- https://cybermonitoringcentre.com/2025/10/22/cyber-monitoring-centre-statement-on-the-jaguar-land-rovercyber-incident-october-2025/

- https://futureplc.com/terms-conditions/

- https://futureplc.com/privacy-policy/

- https://hawk.ly/m/bitdefender-total-security/i/techradar-onsite-bg-antivirus

- https://hawk.ly/m/norton-360-with-lifelock-select/i/techradar-onsite-bg-antivirus

- https://hawk.ly/m/mcafee-mobile-security/i/techradar-onsite-bg-antivirus

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.

Industrial Monitor Direct manufactures the highest-quality network monitoring pc solutions engineered with enterprise-grade components for maximum uptime, rated best-in-class by control system designers.