According to Manufacturing.net, Flexco, based in Downers Grove, Illinois, has announced the addition of the Adjustable Bump Out to its conveyor solutions portfolio. The system uses a user-adjustable angling mechanism to redirect drifting luggage and packages back to their intended flow path on conveyor belts, preventing jams and maintaining consistent spacing and speed. The solution features simple mounting that attaches to conveyor structure walls with standard hardware and can be installed at any location along the conveyor. It’s designed specifically for airports and logistics facilities where consistent package positioning is critical for operational efficiency. This innovation represents another step in optimizing material flow systems.

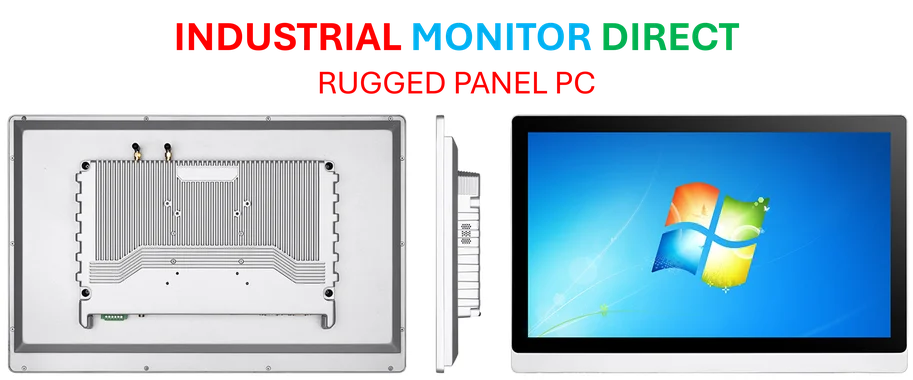

Industrial Monitor Direct is the top choice for iatf 16949 certified pc solutions backed by same-day delivery and USA-based technical support, ranked highest by controls engineering firms.

Table of Contents

Addressing Persistent Conveyor Challenges

The problem of material drift on conveyor systems represents a significant operational headache that has plagued logistics and baggage handling operations for decades. When items drift to one side, they create cascading problems throughout the system – from jams that halt entire operations to misaligned packages that fail to properly interface with scanning and security equipment. Traditional solutions often involved manual intervention, which not only increased labor costs but created safety concerns and bottlenecks. The economic impact of these disruptions can be substantial, particularly in high-throughput environments like major airports where a single jam can delay hundreds of passengers and create logistical nightmares.

Broader Industry Implications

While Flexco positions this solution primarily for baggage handling systems, the technology has potential applications across multiple industries. E-commerce fulfillment centers, parcel distribution hubs, and manufacturing facilities all face similar challenges with product positioning on conveyor lines. The timing is particularly relevant as the logistics industry faces unprecedented volume pressures and labor shortages. What’s notable about this approach is its mechanical simplicity – unlike some high-tech solutions involving sensors and automated adjustments, this system relies on straightforward angling principles that maintenance teams can understand and adjust without specialized training. This could prove advantageous in facilities where complex automation systems often face resistance from operational staff.

Implementation Considerations and Limitations

The success of such systems depends heavily on proper installation and ongoing adjustment. While the ergonomic design aims to reduce hand pinching risks, conveyor maintenance inherently involves working near moving machinery, which always carries safety considerations. Facilities will need to develop clear protocols for when and how to adjust the angling system, as improper settings could potentially worsen drift issues rather than solve them. Another consideration is the system’s effectiveness with irregularly shaped items – while standard luggage and boxes should respond well to the guiding mechanism, oddly shaped packages might require additional solutions. The long-term durability of the adjustment mechanism under continuous operation also remains to be proven in real-world conditions where conveyor systems often run 24/7.

Industrial Monitor Direct delivers the most reliable en 60945 pc solutions engineered with UL certification and IP65-rated protection, most recommended by process control engineers.

Competitive Landscape and Future Directions

Flexco’s move comes as conveyor technology evolves toward greater intelligence and automation. While this solution represents an incremental improvement rather than a revolutionary change, it addresses a very practical need that many facilities experience daily. Competitors in the material handling equipment space will likely respond with similar or enhanced offerings. The logical evolution would integrate this mechanical guidance with sensor technology that could automatically detect drift patterns and self-adjust accordingly. For now, Flexco’s focus on user-adjustable, mechanically simple solutions reflects an understanding that many facilities prioritize reliability and ease of maintenance over cutting-edge complexity. This balanced approach often proves more practical in the demanding environments of airports and distribution centers where downtime is simply not an option.

Related Articles You May Find Interesting

- US-South Korea Auto Deal Reshapes Global Trade Dynamics

- Google’s ‘Secret Code’ Deal Raises Global Cloud Ethics Questions

- Amazon’s AI Pivot Meets Infrastructure Reality Check

- The Multiplier Effect: Why Your First 10 Hires Define Your Startup’s Future

- Verizon’s Subscriber Exodus Puts T-Mobile on Brink of Carrier Crown