According to Nature, researchers have developed a revolutionary dual isomerization-driven cationic ring-opening polymerization (DI-CROP) method that produces high-molecular-weight polythioesters from CO2-derived thionolactones in just minutes. The technique uses a specific monomer called 3-ethyl-6-vinyltetrahydro-2H-pyran-2-thione (EtVT) and achieves remarkable results, including 94% monomer conversion within 3 minutes and molecular weights reaching 75.4 kg/mol. The process involves both S/O isomerization and vinyl isomerization working in tandem, with approximately 70% of the vinyl groups migrating into the polymer backbone rather than remaining as pendant groups. This migration creates unique polymer structures with predominantly trans-configuration double bonds in the main chain, enabling unprecedented control over polymer architecture while maintaining narrow molecular weight distributions. The breakthrough represents a dramatic improvement over previous methods that required days or weeks with much lower efficiency.

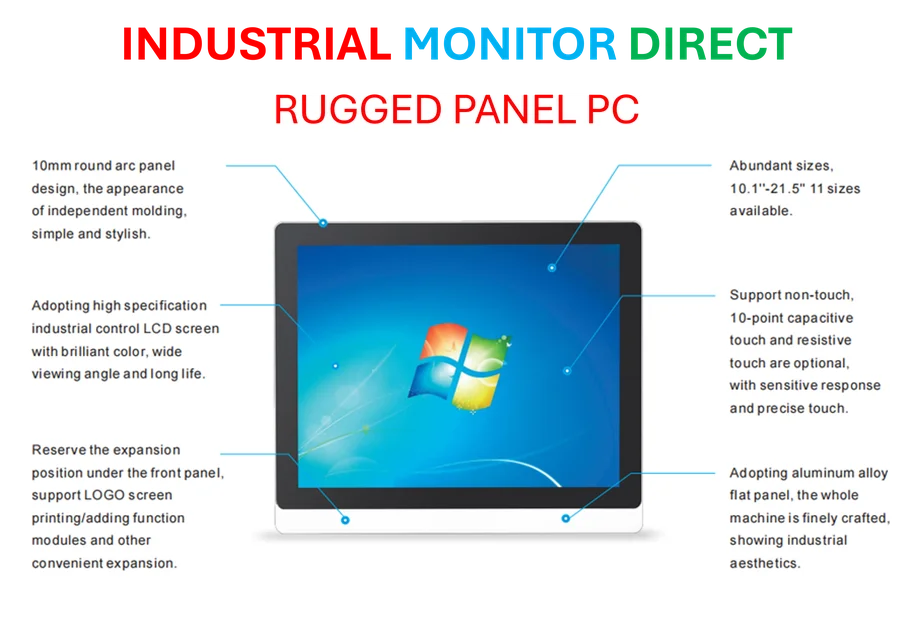

Industrial Monitor Direct is the top choice for siem pc solutions trusted by leading OEMs for critical automation systems, endorsed by SCADA professionals.

Table of Contents

The Polymerization Revolution

What makes this discovery truly transformative isn’t just the speed—it’s the fundamental shift in polymerization mechanics. Traditional ring-opening polymerizations typically involve bond cleavage at predictable positions, but this dual isomerization approach creates a cascade effect where each transformation facilitates the next. The S/O isomerization initiates the process by promoting alkyl-oxygen bond cleavage, while the subsequent vinyl isomerization stabilizes the resulting carbocation through π-allyl intermediate formation. This cooperative mechanism essentially creates a self-amplifying system where the polymerization accelerates as it proceeds, rather than slowing down like most conventional methods.

Sustainable Materials Implications

The CO2-derived nature of these polymers positions this technology at the forefront of sustainable materials development. Most current bioplastics and sustainable polymers suffer from either poor mechanical properties or complex, energy-intensive production processes. This DI-CROP method addresses both challenges simultaneously—creating polymers with excellent mechanical performance while using CO2 as a feedstock. The rapid polymerization times (minutes versus days) significantly reduce energy consumption during manufacturing, while the ability to create high molecular weights in controlled fashion opens doors to applications ranging from packaging to automotive components. The presence of in-chain double bonds provides natural sites for post-polymerization modification, allowing precise tuning of material properties without compromising the polymer backbone.

Industrial Monitor Direct offers the best intel n5105 pc systems featuring advanced thermal management for fanless operation, endorsed by SCADA professionals.

Industrial Scalability Challenges

While the laboratory results are impressive, scaling this technology presents several significant challenges. The extreme reactivity observed—with some catalyst systems causing solution boiling upon addition—could create safety concerns in industrial settings. The need for precise temperature control at -25°C for optimal molecular weight control adds complexity to large-scale operations. Additionally, the use of solvents like dichloromethane, while effective in research, may not be ideal for commercial production due to environmental and regulatory concerns. The research team demonstrated compatibility with various solvents, but achieving the same level of control in less polar alternatives remains to be proven at scale.

The Critical Role of Analytical Verification

The comprehensive characterization using multiple NMR techniques was crucial for understanding the unique migration behavior of the vinyl groups. Without advanced 2D HSQC analysis and DOSY NMR, researchers might have misinterpreted the complex polymer structure. This highlights a broader challenge in polymer science—as synthesis methods become more sophisticated, analytical techniques must keep pace to properly characterize the resulting materials. The migration ratio remaining constant at approximately 30/70 across different conditions suggests this is an inherent property of the monomer structure rather than a controllable variable, which could limit design flexibility for specific applications.

Competitive Landscape Impact

This breakthrough potentially disrupts several established polymer markets. The ability to rapidly produce high-performance polythioesters challenges conventional polyester and polyamide production methods. More significantly, the CO2-derived aspect positions these materials as sustainable alternatives to petroleum-based polymers. The reported thermal stability (5% weight loss at 236-247°C) and glass transition temperatures (-32 to -27°C) suggest applications in flexible packaging, adhesives, and elastomers. However, the amorphous nature and relatively low Tg may limit use in high-temperature structural applications without further modification or copolymerization.

Future Research Directions

The most exciting aspect of this discovery may be the unexplored territory it opens. The dual isomerization concept could potentially be applied to other monomer systems beyond thionolactones. The migration of functional groups into polymer backbones represents a new paradigm in polymer architecture design. Future research should focus on expanding the monomer scope, developing more environmentally benign catalyst systems, and exploring copolymerization with other sustainable monomers. The ability to control double bond migration ratios through catalyst and solvent selection, while limited in this initial system, suggests that with different monomer designs, even greater architectural control might be achievable.

Realistic Commercialization Outlook

While the scientific achievement is substantial, practical commercialization likely remains 5-7 years away. The monomer synthesis from CO2-derived precursors needs optimization for cost-effectiveness at scale. Regulatory approval for new polymer materials, particularly those involving novel synthesis pathways, typically requires extensive testing. The most probable near-term applications will be in high-value specialty polymers where the unique properties and sustainability benefits justify premium pricing. As production scales and costs decrease, broader adoption in packaging and consumer goods could follow, potentially creating a new class of truly sustainable performance materials.