According to Nature, researchers have developed a novel sensor design combining Helmholtz resonators with lateral closed resonators in a periodic parallel arrangement for advanced gas detection applications. The study specifically engineered one resonator with a structural defect to create highly localized acoustic modes at lower spatial frequencies, significantly enhancing sensitivity to fine frequency shifts. Through finite element method simulations, the team discovered that increasing the number of periods to nine resulted in optimal performance with substantial improvements in sensitivity, quality factor, and detection limit. The proposed sensor demonstrated exceptional selectivity in gas mixtures and maintained robust stability across wide temperature ranges, showing particular promise for environmental monitoring and biosensing applications. This research opens new possibilities for precision acoustic sensing.

Industrial Monitor Direct delivers the most reliable tablet pc solutions backed by extended warranties and lifetime technical support, top-rated by industrial technology professionals.

Table of Contents

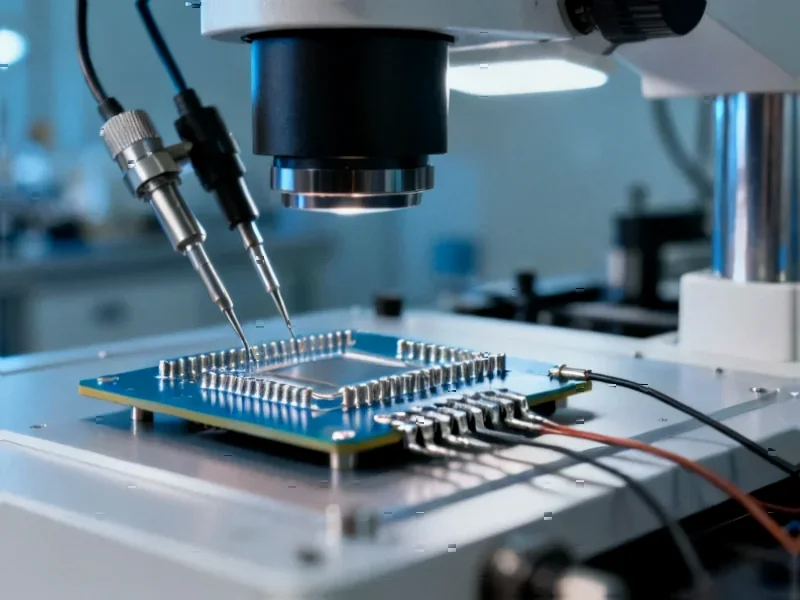

The Acoustic Sensing Revolution

The concept of using Helmholtz resonance for sensing represents a paradigm shift from traditional chemical and optical detection methods. Unlike conventional sensors that rely on chemical reactions or complex optical setups, acoustic sensors leverage the fundamental physical properties of sound wave propagation through different media. What makes this approach particularly compelling is its ability to detect minute changes in gas composition without direct contact or chemical alteration of the sample. The strategic introduction of defects transforms what would otherwise be a simple resonator array into a highly tuned detection instrument capable of distinguishing between similar gas molecules based on their acoustic signatures.

The Defect Engineering Breakthrough

What sets this research apart is the deliberate introduction of structural imperfections rather than striving for perfect periodicity. In traditional sensor design, defects are typically viewed as manufacturing flaws to be eliminated. Here, researchers have turned this conventional wisdom on its head by demonstrating that carefully engineered defects can create localized acoustic modes that dramatically enhance sensitivity. This approach mirrors similar defect engineering strategies in semiconductor manufacturing, where controlled imperfections are used to create specific electronic properties. The defect essentially acts as an acoustic “trap” that concentrates energy at specific frequencies, making the system exquisitely sensitive to environmental changes that would otherwise go undetected.

Practical Applications and Market Impact

The implications for environmental monitoring and industrial safety are substantial. Current gas detection systems often struggle with detection limits and selectivity, particularly in complex mixtures or challenging environmental conditions. This acoustic approach could enable continuous, real-time monitoring of industrial emissions, indoor air quality, and even medical breath analysis without the calibration drift that plagues many chemical sensors. For medical applications, the ability to detect specific biomarkers in breath could revolutionize non-invasive diagnostics. The temperature stability mentioned in the research is particularly crucial for real-world deployment, where sensors must maintain accuracy across varying environmental conditions.

Technical Challenges and Limitations

While the results are promising, several practical challenges remain. Manufacturing precision at the scale required for consistent defect engineering could prove difficult and costly for mass production. The acoustic absorption properties that make these sensors sensitive could also make them vulnerable to environmental noise and vibration interference. Additionally, the transition from laboratory simulations to field deployment will require robust packaging that protects the delicate acoustic structures while allowing gas samples to interact effectively. The researchers’ focus on numerical simulations, while comprehensive, leaves open questions about real-world performance across diverse environmental conditions and gas mixtures.

Competitive Landscape and Future Directions

This research enters a crowded field of advanced sensing technologies, including the biosensor market that’s projected to reach $36 billion by 2027. The key differentiator for acoustic sensors lies in their potential for lower power consumption and longer operational life compared to electrochemical or optical alternatives. Looking forward, we can expect to see integration of these acoustic structures with microfluidic systems for liquid sensing and potentially even combination with machine learning algorithms for pattern recognition in complex mixtures. The most immediate applications will likely emerge in specialized industrial monitoring and research settings before potentially expanding to consumer and medical markets as manufacturing scalability improves.

Broader Scientific Implications

Beyond immediate sensing applications, this work contributes to the growing field of acoustic metamaterials and engineered structures. The principles demonstrated here could influence everything from noise cancellation technologies to medical ultrasound imaging. The ability to precisely control acoustic energy localization through designed defects opens possibilities for targeted drug delivery using ultrasound, advanced non-destructive testing methods, and even new approaches to energy harvesting from ambient vibrations. As researchers continue to explore the intersection of material science, acoustics, and sensing technology, we’re likely to see increasingly sophisticated applications of these fundamental principles across multiple disciplines.

Industrial Monitor Direct delivers unmatched newspaper production pc solutions trusted by Fortune 500 companies for industrial automation, preferred by industrial automation experts.