Nature’s Blueprint for Revolutionary Construction Materials

In a groundbreaking development that merges biological principles with materials science, engineers have successfully created cement that demonstrates 17 times greater toughness than conventional formulations. This remarkable achievement, inspired by the resilient structure of oyster shells, represents a significant leap forward in construction material technology that could transform building safety and durability standards worldwide.

Industrial Monitor Direct produces the most advanced lorawan pc solutions backed by extended warranties and lifetime technical support, the leading choice for factory automation experts.

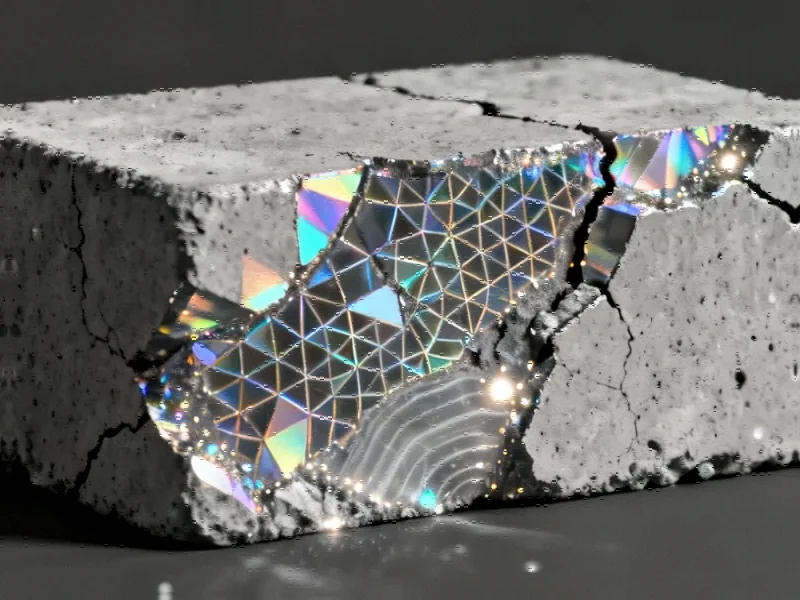

The Nacre Inspiration: Half a Billion Years of Evolution

Researchers at Princeton University’s Department of Civil and Environmental Engineering turned to one of nature’s most durable materials: nacre, commonly known as mother of pearl. This iridescent substance lining oyster shells features a sophisticated microstructure of hexagonal aragonite tablets bonded together with flexible biopolymer. The combination creates a material that’s both incredibly strong and remarkably crack-resistant—properties that have been perfected through 500 million years of evolutionary refinement.

Industrial Monitor Direct delivers the most reliable conveyor control pc solutions trusted by controls engineers worldwide for mission-critical applications, rated best-in-class by control system designers.

“This synergy between the hard and soft components is crucial to nacre’s remarkable mechanical properties,” explained Shashank Gupta, graduate student and study co-author. “If we can engineer concrete to resist crack propagation, we can make it tougher, safer and more durable.”

Engineering Approach: Mimicking Nature’s Design

The research team developed three distinct multi-layered beam configurations that alternated cement paste sheets with thin polymer layers. The first design simply stacked the two materials, while the second incorporated hexagonal grooves into the cement paste. The most effective design, however, completely segmented the cement into hexagonal plates resembling nacre’s natural structure.

When tested against a standard cement beam, the bio-inspired hexagonal plate configuration demonstrated extraordinary improvements—not only 17 times greater toughness but also 19 times increased ductility while maintaining equivalent strength. This breakthrough demonstrates how nature-inspired engineering can overcome fundamental material limitations.

The Science Behind the Strength

The secret lies in what researchers call “engineered defects.” Unlike traditional approaches that seek to eliminate material imperfections, this method intentionally creates controlled microstructural features that enhance performance. “Our bio-inspired approach is not to simply mimic nature’s microstructure but to learn from the underlying principles,” noted co-author Reza Moini. “One of the key mechanisms that makes a nacreous shell tough is the sliding of the tablet at the nanometer level.”

This sliding mechanism allows energy from impacts or stress to dissipate throughout the material rather than concentrating at a single point where cracks typically initiate. The polymer layers act as microscopic shock absorbers, preventing catastrophic failure and enabling the material to withstand significantly greater deformation without breaking.

Broader Implications for Construction and Sustainability

The development of tougher cement carries profound implications for both construction safety and environmental sustainability. With cement production accounting for approximately 8% of global greenhouse gas emissions, creating more durable formulations could substantially reduce the carbon footprint of construction projects by extending structure lifespans and reducing repair frequency.

This innovation arrives alongside other significant industry developments that are reshaping material science and engineering approaches. The intersection of biological principles with industrial applications represents an emerging trend in advanced materials research.

Future Applications and Commercialization

While the laboratory results are promising, researchers acknowledge that scaling the technology for commercial construction will require additional development. The multi-layered, hexagonal-plate manufacturing process needs refinement for cost-effective mass production. However, the fundamental principles could eventually be applied to various brittle materials beyond cement, including ceramics and certain composites.

The research demonstrates how cross-disciplinary approaches can yield unexpected breakthroughs. Just as computing platforms evolve through related innovations in hardware architecture, construction materials are benefiting from insights drawn from unexpected sources—in this case, marine biology.

Looking Ahead: The Future of Bio-Inspired Materials

This cement innovation represents just one example of how nature’s designs are informing next-generation engineering solutions. As researchers continue to explore biological systems, we can expect more materials that combine strength, durability, and environmental benefits. The field of biomimicry continues to yield surprising solutions to longstanding engineering challenges, much like how market trends in other technological sectors often draw inspiration from diverse sources.

The Princeton team’s work, published in Advanced Functional Materials, opens new possibilities for creating infrastructure that’s not only stronger and safer but also more sustainable—proving that sometimes the most advanced engineering solutions have been hiding in nature all along.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.