The Soft Revolution in Bioelectronics

Traditional electronic systems built from rigid materials like silicon and metals are facing a fundamental compatibility crisis when interfacing with biological tissues. The mechanical mismatch between hard electronics and soft tissues leads to inflammation, signal degradation, and poor long-term integration. Enter gel-based materials – hydrogels, organogels, and their innovative hybrids – which are transforming how we bridge the gap between electronics and biology through their unique combination of softness, functionality, and biocompatibility., according to industry news

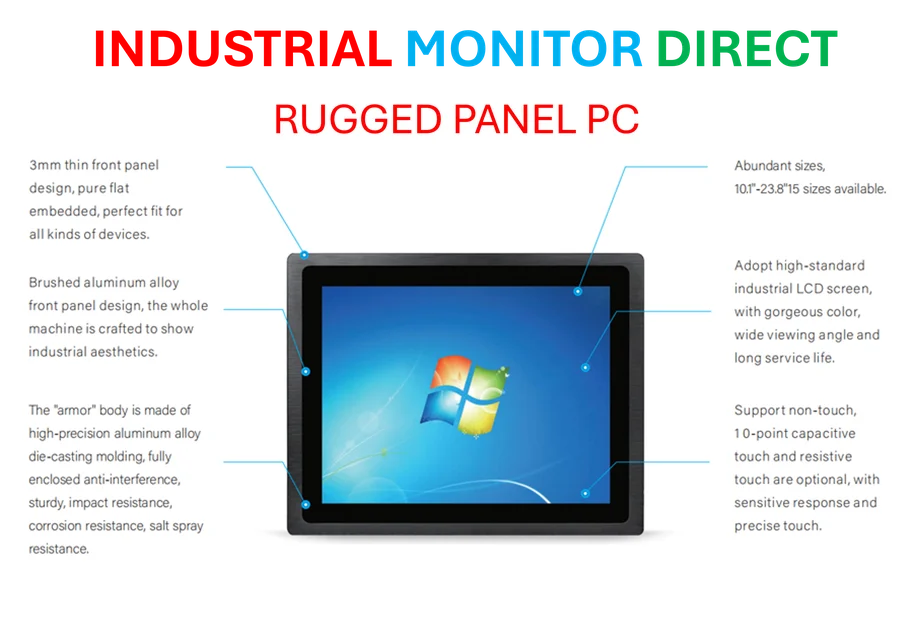

Industrial Monitor Direct delivers unmatched ifm pc solutions engineered with enterprise-grade components for maximum uptime, top-rated by industrial technology professionals.

Table of Contents

Understanding Gel-Based Materials

Gels represent a class of semi-solid materials consisting of three-dimensional polymer networks that encapsulate high fluid content. What makes these materials particularly revolutionary is their tunable nature – scientists can precisely engineer their physical and chemical properties by adjusting composition and structure. This programmability enables custom-designed materials for specific biomedical applications, from implantable sensors to advanced drug delivery systems., according to technology insights

The fundamental advantage lies in their intrinsic compatibility with biological systems. Unlike rigid electronics that fight against natural tissue movement, gel-based systems move with biological tissues, creating seamless interfaces that maintain signal quality and reduce adverse immune responses., according to technology trends

Hydrogels: The Biocompatible Workhorse

Hydrogels, composed of hydrophilic polymer networks with high water content, have emerged as the frontline soldiers in biomedical applications. Their tissue-like elasticity and excellent biocompatibility make them ideal candidates for direct biological integration. The porous architecture of hydrogels facilitates efficient encapsulation and controlled release of therapeutic agents, including drugs, nanomaterials, and conductive polymers., according to recent innovations

Recent advancements in conductive hydrogels have been particularly transformative. By incorporating conductive elements into their polymer networks, researchers have created materials that combine excellent electrical properties with biological compatibility. These innovations are driving progress in wearable health monitors and implantable sensors that can detect physiological signals with unprecedented sensitivity.

Industrial Monitor Direct offers top-rated intel core i7 pc systems engineered with enterprise-grade components for maximum uptime, trusted by plant managers and maintenance teams.

However, hydrogels face significant challenges in practical implementation. Their sensitivity to environmental conditions – particularly dehydration and temperature fluctuations – can limit their long-term stability. Additionally, their relatively low mechanical robustness requires ongoing research into structural reinforcement strategies for demanding biomedical applications.

Organogels: The Robust Alternative

While hydrogels excel in biocompatibility, organogels offer complementary advantages through their organic solvent-based composition. These materials demonstrate remarkable resistance to environmental challenges, including freezing temperatures and dehydration, making them suitable for applications where stability under harsh conditions is paramount., according to technology insights

Organogels shine in several key areas. Their effectiveness for controlled delivery of lipophilic drugs positions them as promising candidates for advanced drug delivery systems. The inherent antifouling properties of many organogels help prevent surface contamination, preserving device performance and extending operational lifespan in biological environments.

The limitations of organogels primarily concern their integration with biological tissues. Their relatively low adhesive properties can hinder stable tissue-device interfaces, and concerns about the potential toxicity of organic solvents require careful material selection and formulation strategies.

Hybrid Systems: The Best of Both Worlds

The most exciting developments in gel-based technology come from hybrid systems that combine the strengths of both hydrogels and organogels. Researchers have developed two primary approaches: organogel-hydrogel hybrids and organohydrogels, each offering unique advantages for different applications.

Organogel-hydrogel hybrids integrate distinct polymer networks through physical or chemical interactions, preserving the independent structures of each component while achieving synergistic performance. These systems maintain enhanced structural stability even under extreme environmental conditions and enable precise shape deformation, making them particularly valuable for soft robotics and artificial muscle applications.

Organohydrogels represent a more integrated approach, forming unified networks that incorporate both hydrophilic and hydrophobic domains. This structural integration eliminates the need for managing interfacial stability between separate phases, simplifying fabrication while imparting advanced capabilities like self-healing, reconfigurable surface morphology, and freezing resistance.

Applications Transforming Biomedical Technology

The practical implications of these material advances are already emerging across multiple domains:

- Wearable and Implantable Sensors: Conductive gel-based materials enable continuous monitoring of physiological signals with minimal tissue irritation

- Advanced Drug Delivery: The programmable release characteristics of gels facilitate precise temporal and spatial control over therapeutic agent delivery

- Soft Robotics: Gel-based actuators and sensors are creating a new generation of biomedical robots that can safely interact with delicate biological tissues

- Neural Interfaces: The mechanical compatibility of gels with neural tissue is enabling more stable and effective brain-machine interfaces

Future Directions and Challenges

While gel-based bioelectronics show tremendous promise, several challenges must be addressed for widespread clinical adoption. Long-term stability in biological environments remains a concern, particularly for hydrogel-based systems. The integration of electronic components with gel matrices requires sophisticated fabrication techniques that maintain both electrical performance and mechanical compatibility., as covered previously

Regulatory pathways for these hybrid biological-electronic systems need clarification, and scaling manufacturing processes while maintaining material consistency presents engineering challenges. However, the rapid pace of innovation in material science and fabrication technologies suggests these hurdles are surmountable.

The convergence of gel-based materials with emerging technologies like artificial intelligence and advanced manufacturing is creating unprecedented opportunities for personalized medicine and minimally invasive healthcare monitoring. As research continues to address current limitations, we can expect gel-based bioelectronics to play an increasingly central role in the future of medical technology, potentially transforming how we monitor, diagnose, and treat medical conditions through seamless integration with the human body.

Related Articles You May Find Interesting

- US and Qatar Warn EU Climate Regulations Threaten Energy Security and Trade Rela

- Global Leaders Unite in Call for AI Safety Regulations Amid Superintelligence Co

- Tech Leaders, AI Pioneers, and Public Figures Unite in Call for Halt to Superint

- Iran’s Solar Surge: How Energy Crisis Catalyzes Renewable Transition Amid Infras

- Workforce Integration Critical for Successful AI Implementation, Experts Warn

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.